3d printing is a new efficient additive manufacturing technology. During the 3d printing process, metal powder or adhesive materials with a plastic shrinkage characteristic are used in a 3d printer to print layer by layer, which is the principal method to perform additive manufacturing. This new additive manufacturing technology is extensively used in the areas of product design and prototyping, medical product manufacturing, vehicle design, engineering, spaceflight, etc. Ceramic 3d printing is used to create the ceramic prototypes. There are 2 types of ceramic 3d printing:

- Indirect 3d printing

- Direct 3d printing

Compared with forming in traditional ways, forming with 3d printing is more rapid and efficient, with a lower manufacturing cost for ceramic products. A 3d-printed-product from a computer-aided design has a higher precision than a hand-made ceramic article. The 3d printer is the essential equipment for 3d printing. It has an extruder whose position is precisely controlled by embedded chips. These chips can control the quantities of material extruded and the extrusion time. In addition to high dense ceramic slip, the plastic filament can also be printed directly and it is the best material to use for indirect 3d printing of a product.

Working of Ceramic 3d printing

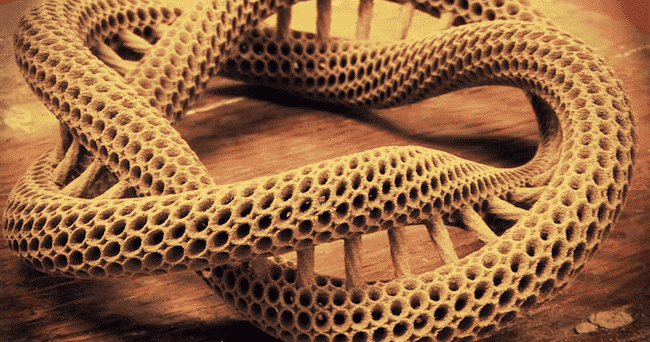

Industrial-grade printing technology is used to create ceramic prints. The printer builds a 3d model, from bottom to top, one layer at a time. First, the printer’s rolling mechanism spreads a thin layer of ceramic powder on a platform, and a print head places organic binder at specific locations. This is the first paper-thin layer of the model.

The platform then drops down and the roller spreads another layer of powder. Then, this process is repeated – one layer at a time – until the model is finished. By the time the printing is complete, the model sits in a thick bed of cushiony-fine alumina-silica ceramic powder.At this point, the model is removed from the printer and placed in a drying oven. The drying oven strengthens the model dramatically, although it’s still fragile at this point. We call this the ‘green state’.

After drying, the model is extracted from the powder bed and excess powder is removed. It’s then fired in an oven to gain more strength. At this point, a pre-glaze coating is applied. The coating is dried and then fired for the second time. In the last step, the model is glazed and fired for the final time. Now, the shiny smooth glaze coating is visibly glossy.

Benefits of Ceramic 3d printing

There is a pre-ceramic resin that can be used for 3d printing complex shapes just like regular polymers. This ceramic material can withstand up to 1700° Celsius or 3092° Fahrenheit. This minimizes the limitations of ceramic 3d printing and opens up new doors for creating more complex 3d designs out of ceramic.

The resulting objects from this material are expected to have superior qualities compared to their counterparts. So in addition to printing ceramic household materials, one can also print scientific lab equipment with the ability to withstand high temperatures.

With 3d printing ceramics, one has a wide variety of color choices. There are the basic color choices like black, white, blue, red, green, orange, and yellow. Some professional 3d printing services also offer ceramic models in colors like turquoise and subtle shades of anise green and oyster blue. So regardless of what one needs to print using a ceramic 3d printer, one will have a series of choices in color.

3d printed ceramic pot

Currently, ceramic is the only known 3d printing material that is food safe. In the process of creating and glazing the material, a type of gloss that is non-toxic and lead-free is used. This means that one can use it to print utensils like cups, plates, bowls, and other kitchen tools.

3d printed ceramic cups and plates

Basically, one can safely print tableware and home décor in which you’re going to serve food or beverages. Otherwise, it’s also commonly used for creating vases, candle holders, art, and many more.