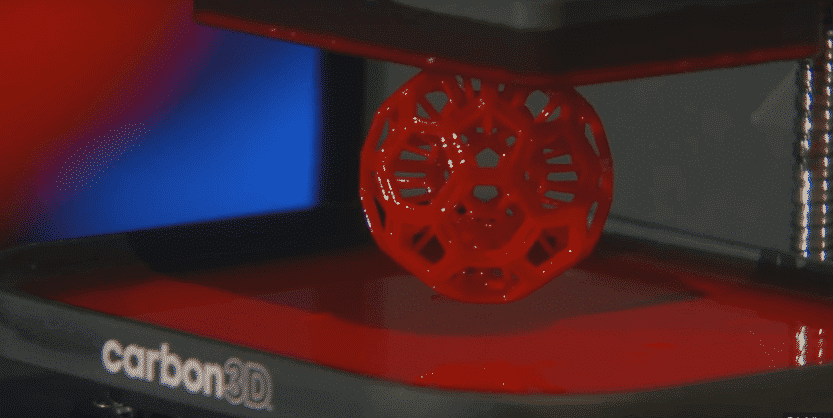

Carbon, a 3d printing service startup from the U.S has launched M1 3d printer, the fastest 3d printer in the world. A new technology called CLIP (Continuous Liquid Interface Production) is used in the processing. The material is built in series instead of the layer by layer manufacturing. Thermoset materials and the type of resin plays an important role in the manufacturing of the end product.

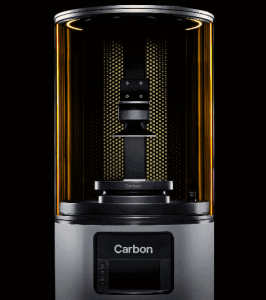

M1 3d printer

How does fastest 3d printer in the world works?

The M1 3d printer uses CLIP technology building the material in a continuous fashion rather than the layering production. The printer also works on balancing the light power and the oxygen content present in the air. This involves a two-step process where the first step is the setting of shape with light and oxygen and the mechanical properties are determined from the chemistry of resin being used. The entire part comes out of the resin vat where the initial build is immersed. When the part moves up, the gap created automatically covers up as the resin moves inward due to gravity. All these processes occur quickly and the entire process is completed within a short span of time. By using CLIP technology and by controlling the amount of oxygen the built material comes out with good quality.

Post processing involves removing excess liquid from the built material taken out from the liquid resin vat and curing which is carried out to complete the setting of the thermoset.

The CLIP Technology allows designers to make complex designs that are constrained by layer by layer manufacturing. Prime most advantage is the direct use of manufactured part without any further optimization of the part produced. CLIP technology is one of the greatest alternatives to the existing 3d printing technologies and is implemented in Fortune companies like BMW, Adidas, etc.

Read more: