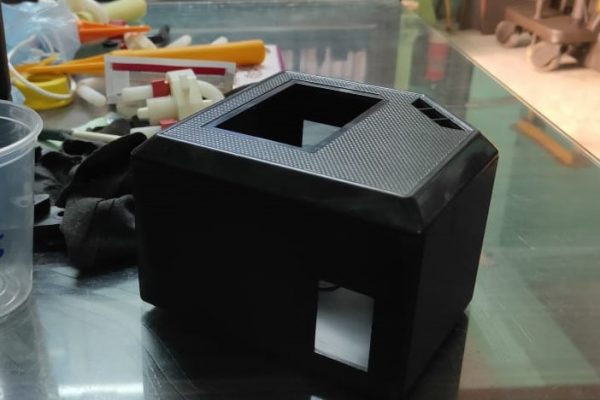

3D Printing Enclosure for Safer, Cleaner & More Consistent Prints

Make your products look beautiful

A lot of companies go with sheet metal bending because they find it cheap and fast. It leaves the product dull and heavy which impacts purchase by a customer. It has a rough look which does not look like a finished product

Using customized 3D printed product cases

With 3D printing you can make your product look clean and smooth at the same cost with faster time. A light weight and colored product is sure to impress. Customize your case to your product and make it look compact with your brand.

Our end to end product development support process

01. Design

We first analyze your product components and then understand its usage. We then make a 3D CAD design of your product which will be compact, ergonomical and user friendly. ( 3 – 5days )

02. Prototype

Once the initial design is finalized, we 3D print the prototype for you in the best material for your usability. The prototype is then post processed to give a smooth finish. ( 1 – 3days )

03. Manufacture

After the prototype, depending upon the quantity and the frequency we manufacture your product in the range of 1 – 5000+ using methods like 3D printing, vacuum casting , injection molding.

Beauty at its best

Contact us and make your product stand out

Nobody stopped us from sharing Testimonials !

Our happy clients