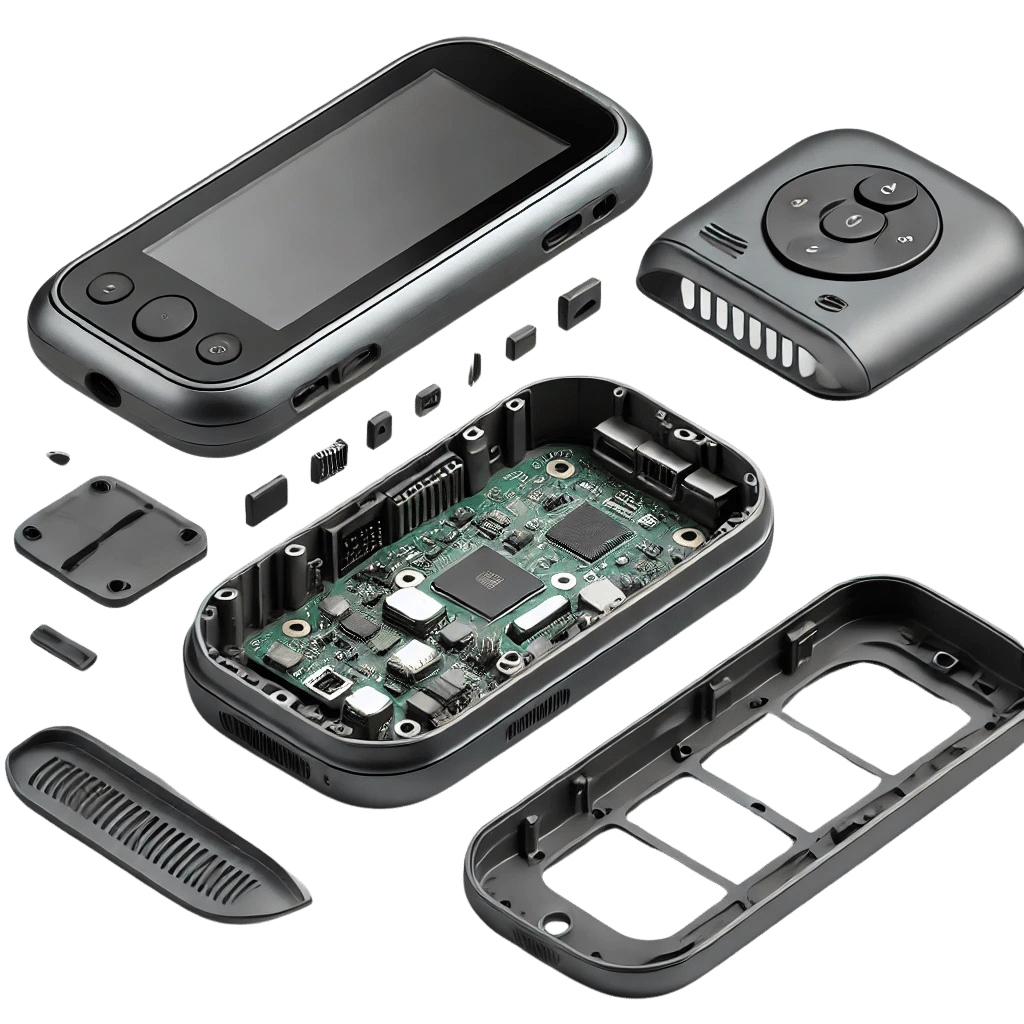

Stop limiting your product by designing PCB for existing enclosures. Design a custom enclosure for your PCB

Customized Enclosures designed for your PCB

Why design Custom enclosures

Custom enclosures are important for the protection, functionality, and aesthetics of your product. A well-designed enclosure ensures customized layout, heat dissipation, and protection from external factors like moisture, dust, and impact.

Aesthetics

It makes a huge difference when you give a standard enclosure off the market shelf vs when you give your own custom branded enclosure designed with your product in mind

More control

Better control with your electronics since you do not need to spend time redesigning your electronics to fit the existing enclosures in the market

Our Enclosure Design Capabilities

We specialize in converting product ideas and PCB layouts into manufacturable, aesthetic enclosures. Whether you’re building an IoT device, a sensor unit, or a custom handheld gadget, our design capabilities are tailored to help startups get to production faster

PCB fitment

We start by understanding your PCB layout and port placements. Our enclosures are precisely designed to house your components with exact cutouts, standoffs, and mounting features to ensure seamless internal fit and protection.

Thermal and Airflow

If your device generates heat, we design with thermal management in mind — incorporating vents, heat sink slots, or airflow channels to prevent overheating and ensure optimal performance in the field.

Aesthetic meets Functional

We strike a balance between sleek industrial design and rugged functionality. Whether you want a clean, consumer-friendly look or a rugged industrial enclosure, we design with your product’s environment and use-case in mind.

Manufacturing-Ready Detailing

From snap-fit joints to screw bosses and wall thickness optimization, we design with the chosen manufacturing method and material in mind — ensuring your enclosure is injection molding-ready from day one.

Why choose us

Unleash your design and make it into reality

Manufacturing support

We guide and help you manufacture your product right from design to production

Experienced designers

Our designs are geared so that you don’t face any problems when manufacturing

No MOQ

We do not have any MOQ and scale production as you scale up your product

Material diversity

Choose from 50+ materials and finishes for your product as you want it.

Some of our projects

What do you get working with us

Transparency at every step

Frequently asked questions – Enclosure design

What information do you need to get started on my enclosure design?

We typically need your PCB file (in STEP or similar format), details about ports, buttons, display requirements, mounting preferences, and any specific environmental or functional needs. If you don’t have a PCB file, we can work with photos, sketches, or dimensions too.

Can you help me if I don’t have a finalized PCB yet?

Yes! We frequently work with startups in the early prototyping stage. We can begin the enclosure design using your preliminary PCB layout or dimensions and update it later once the board is finalized.

Do you offer concept sketches or just CAD models?

We provide both. If you’re still exploring enclosure aesthetics, we can share quick concept renders before moving into detailed CAD development.

Can I use your enclosure design for injection molding?

Absolutely. All our designs are optimized for injection molding — with correct draft angles, ribs, snap-fits, and moldability checks. We ensure the design is DFM (Design for Manufacturing) compliant from day one.

Do you handle design for 3D printing or CNC too?

Yes. If you’re planning a prototype via 3D printing or CNC before mass production, we adapt the enclosure accordingly — adjusting wall thicknesses, tolerances, and assembly methods.

Will the enclosure design include internal supports and fastening features?

Yes, we add bosses for screws, snap-fits, slots for PCB mounting, and other internal features as needed. Our goal is to make assembly smooth and reliable.

Can I request changes after the initial design?

Definitely. We include 2–3 rounds of revisions in our standard package. Your feedback matters, and we ensure the design evolves to meet your expectations.

How long does the enclosure design process take?

Typically 5–7 working days, depending on complexity and responsiveness during reviews. Urgent timelines can be accommodated on request.

Can you also manufacture the enclosure once the design is complete?

Yes! We offer end-to-end services — from design to prototyping and low-volume injection molding (as low as 100 pieces)