ABS Injection molding

Automotive parts

Enclosures

Construction

Appliances

Advantages of ABS injection molding

ABS is a good material when you need both strength and durability with temperature resistance. Its one of the most widely used plastic across different industries due to its low cost

- Good dimension stability

- Heat resistance

- Impact resistance

- Easy to machine

- Can be made Flame and UV retardant

ABS Injection molding grades

We help you make ABS injection molded parts with the properties you need

Standard ABS grades

- General grade ABS

- High impact ABS

- High flow ABS

- Transparent ABS

Special ABS grades

- Fire retardant ABS

- UV grade ABS

- Glass filled ABS

- PC ABS

Finishing options for ABS parts

Wide color range

Product texture

Electroplating

Painting

Design guidelines for ABS Injection molding

Minimum wall thickness for ABS parts

A minimum wall thickness of 1.2mm to a maximum of 3mm should be maintained for ABS parts. Lower wall thickness will cause filling issues while higher wall thickness will cause sink marks on the part

Uniform wall thickness

A uniform wall thickness should be maintained throughout the part to ensure smooth flow of material. Inconsistent wall thickness will hamper filling

Draft angles

Sharp corners

A fillet has to be added in all sharp corners to ensure easy flow of material

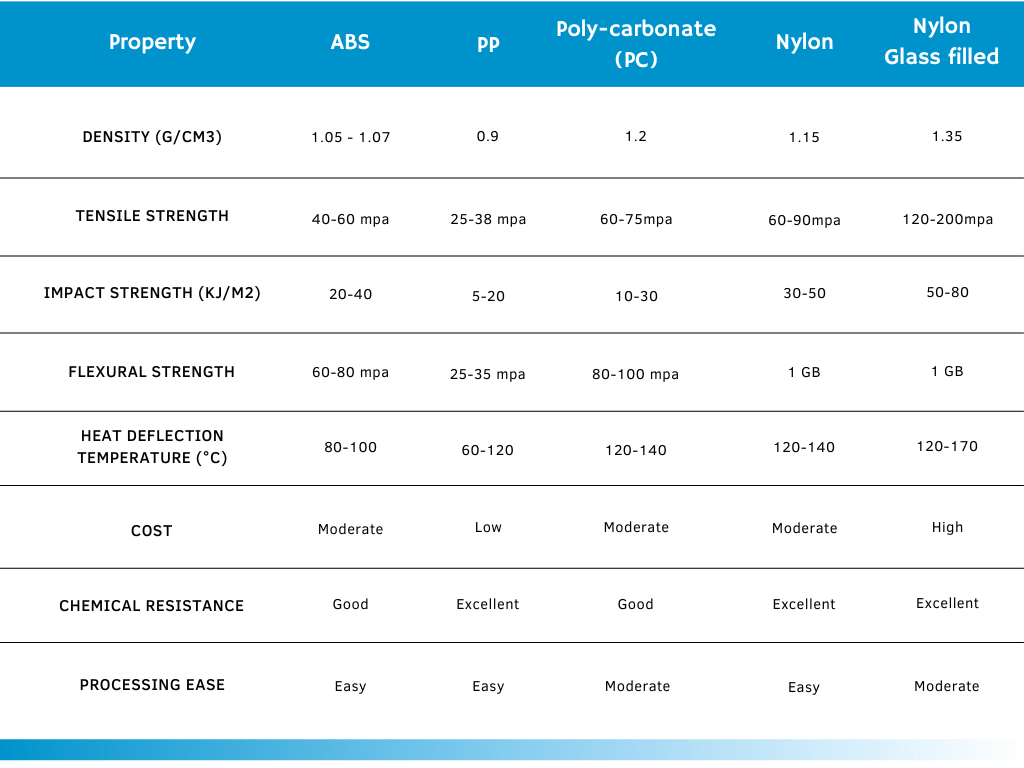

Comparison of Injection molded plastics