POM & Delrin Injection Molding

Automotive parts

Gears

Construction

Appliance parts

Advantages of Delrin injection molding

Delrin is a good material when you need both strength and durability with temperature resistance. Its one of the most widely used plastic to make gears, washers and spacers. Mainly used for making parts with friction as it has self lubricating properties

- Good dimension stability

- Heat resistance

- Impact resistance

- Self lubricating

- Good for mechanical parts

ABS Injection molding grades

We help you make Delrin injection molded parts with the properties you need

Delrin common names

- POM

- Acetal

- Poly acetal

Finishing options for Delrin parts

Wide color range

Product texture

Electroplating

Painting

Design guidelines for Delrin Injection molding

Minimum wall thickness for Delrin parts

A minimum wall thickness of 0.8mm to a maximum of 3.2mm should be maintained for Delrin parts. Lower wall thickness will cause filling issues while higher wall thickness will cause sink marks on the part

Uniform wall thickness

A uniform wall thickness should be maintained throughout the part to ensure smooth flow of material. Inconsistent wall thickness will hamper filling

Draft angles

Sharp corners

A fillet has to be added in all sharp corners to ensure easy flow of material

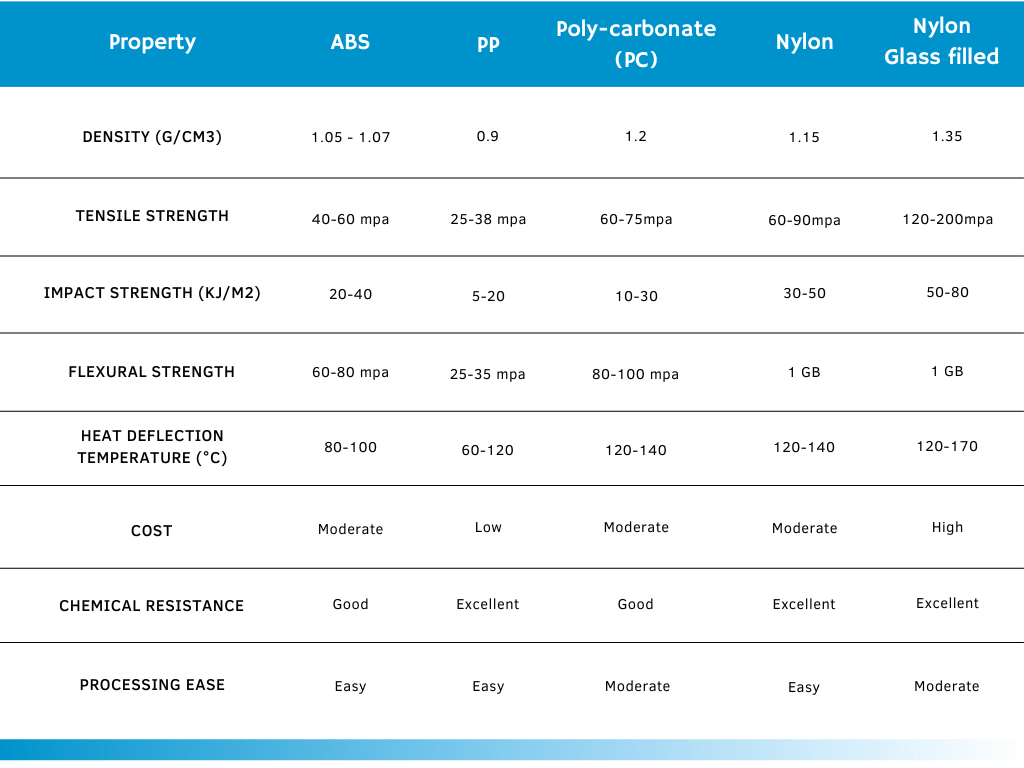

Comparison of Injection molded plastics