Leverage 3D printing and low volume injection molding to get your enclosure manufactured with MOQ starting at 100 pieces

Get Enclosures manufactured for your devices

Why choose us for manufacturing your enclosures

At Precious3D, we specialize in cost-effective, low-volume production of plastic and metal enclosures tailored for hardware startups and product innovators. Whether you’re preparing for a pilot launch or need short-run production for niche devices, we simplify manufacturing without compromising on quality.

Low MOQ, High quality

We support production starting from just 100 pieces, making it accessible for startups. Perfect for MVPs, early-stage batches, and market testing.

Rapid Injection Molding

Get access to rapid tooling and cost-efficient molds with expert design validation, mold flow optimization, and DFM analysis.

Flexible Material Options

Choose from a wide range of engineering plastics like ABS, PC, PP, Nylon, or request custom blends suited for your application (heat resistance, UV stability, etc.)

Production + Prototyping

Start with a 3D printed prototype or CNC sample and seamlessly move into injection molding production—all in one workflow.

Our Enclosure Manufacturing Capabilities

We specialize in converting product ideas and PCB layouts into manufacturable, aesthetic enclosures. We work with multiple technologies to make sure your product gets manufactured in the material and quantity you need

Early-Stage Production

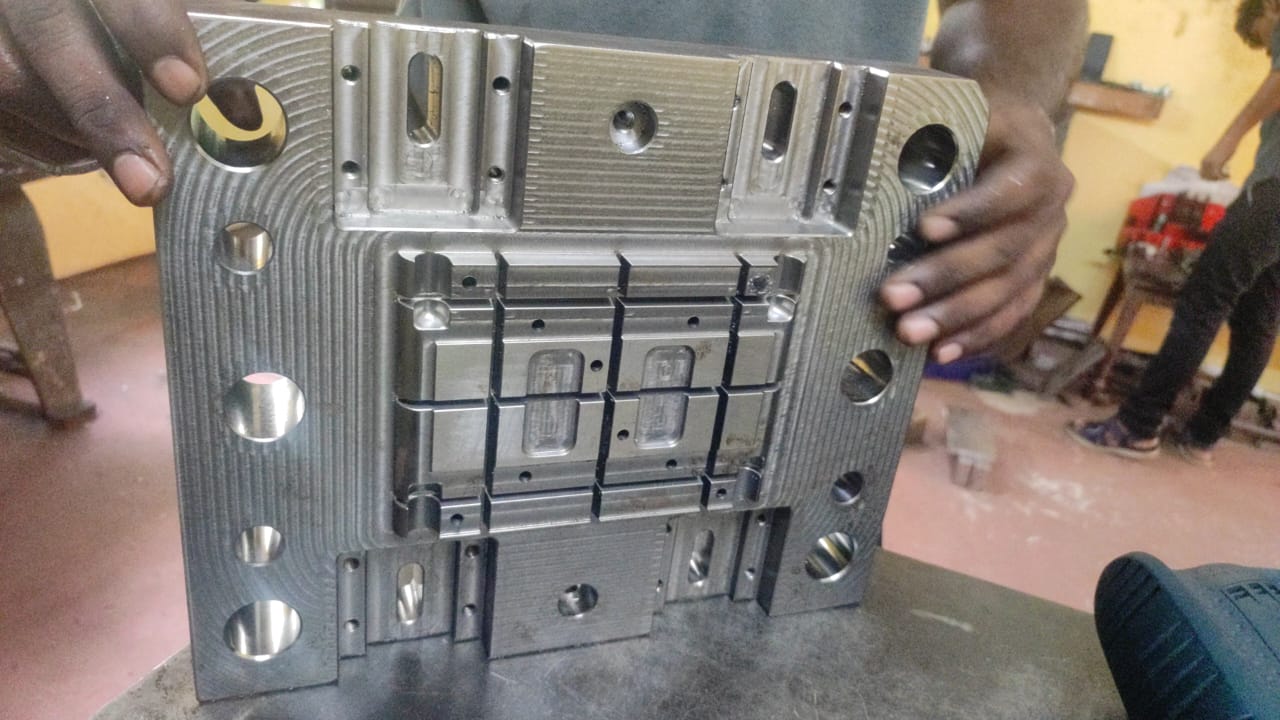

01. Low volume molds

We specialize in fast, startup-friendly tooling solutions that help you get to market quickly without burning your budget. Depending on your need, we offer both 3D printed molds and low-volume metal molds:

3D Printed Molds: Perfect for testing fit, form, and function. Ideal for 5–50 parts, or when you need feedback before committing to metal tooling.

Metal Hand Molds: Suitable for 100–5,000 parts. These are great for early product launches, pre-orders, or bridge production before mass manufacturing.

Mass Manufacturing

02. Heavy duty production

When you’re ready to scale, we offer H13 or P20 hardened steel molds designed for full automation and high-volume production. These molds are built to last and deliver consistent quality across thousands of parts.

Suitable for: 10,000+ cycles

Features: Hot runners, automated ejection, tight tolerances

Materials: All major plastics supported (ABS, PC, Nylon, etc.)

Custom Sheet Metal Fabrication

03. Sheet metal designs

Need a tougher enclosure or something with a metallic finish? We offer CNC-bent sheet metal enclosures for electronics that require strength, EMI shielding, or an industrial look.

Material options: Mild steel, stainless steel, aluminum

Finish: Powder coating, anodizing, brushing, or plating

Applications: Industrial control panels, sensor housings, and rugged IoT devices

Why Choose Our Enclosure Manufacturing Expertise

Unleash your design and make it into reality

Manufacturing support

We guide and help you manufacture your product right from design to production

Experienced designers

Our designs are geared so that you don’t face any problems when manufacturing

No MOQ

We do not have any MOQ and scale production as you scale up your product

Material diversity

Choose from 50+ materials and finishes for your product as you want it.

Some of our projects

What do you get working with us

Step by step process

Frequently Asked Questions – Enclosure Manufacturing

What’s your MOQ for enclosure manufacturing?

We support orders starting from 100 pieces—perfect for early-stage startups or small-volume hardware launches.

How much does an injection mold cost?

Tooling starts at around 50000 INR depending on complexity. We’ll guide you on optimizing the mold to keep costs low.

Can you handle both prototyping and production?

Yes. We offer 3D printing, CNC machining, and injection molding to cover your entire product lifecycle.

What are your lead times?

Tooling: 2–3 weeks

Samples: 5–7 days after tooling

Production: 7–10 days after sample approval

Can I send my own design?

Absolutely. Just share your files (STEP/IGES preferred), and we’ll validate and prepare them for mold-making

What quality checks do you follow?

We conduct dimensional checks, visual inspections, and functional tests. You can also request reports or third-party QC.

What finishes and colors are available?

We offer glossy, matte, textured, and custom Pantone matching finishes. Let us know your preference.

Can I get just the enclosure without electronics?

Yes. We strictly focus on enclosure design and manufacturing. You can integrate your electronics afterward.

Can you ship to the US or Europe?

Yes! We export globally with full documentation and support, whether by air or sea freight.