Polypropylene (PP) Injection molding

Toys

Enclosures

Medical

Appliances

Advantages of Polypropylene (PP) injection molding

Polypropylene (PP) is a good material when you need a durable low cost plastic. Its one of the most widely used plastic in the toys and medical industry. There are some applications for the automotive and appliance industry as well. Its easy to manufacture components using PP and its available in a wide variety of colors

- Flexibility

- Food safe

- Easy to mold

- Cheap cost

PP Injection molding grades

We help you make Polypropylene (PP) injection molded parts with the properties you need

Standard PP grades

- General grade PP

- PPCP (more stiffer)

- Talc filled PP

Finishing options for PP parts

Wide color range

Product texture

Electroplating

Painting

Design guidelines for Polypropylene (PP) Injection molding

Minimum wall thickness for ABS parts

A minimum wall thickness of 0.6mm to a maximum of 3.5mm should be maintained for PP parts. Lower wall thickness will cause filling issues while higher wall thickness will cause sink marks on the part

Uniform wall thickness

A uniform wall thickness should be maintained throughout the part to ensure smooth flow of material. Inconsistent wall thickness will hamper filling

Draft angles

Sharp corners

A fillet has to be added in all sharp corners to ensure easy flow of material

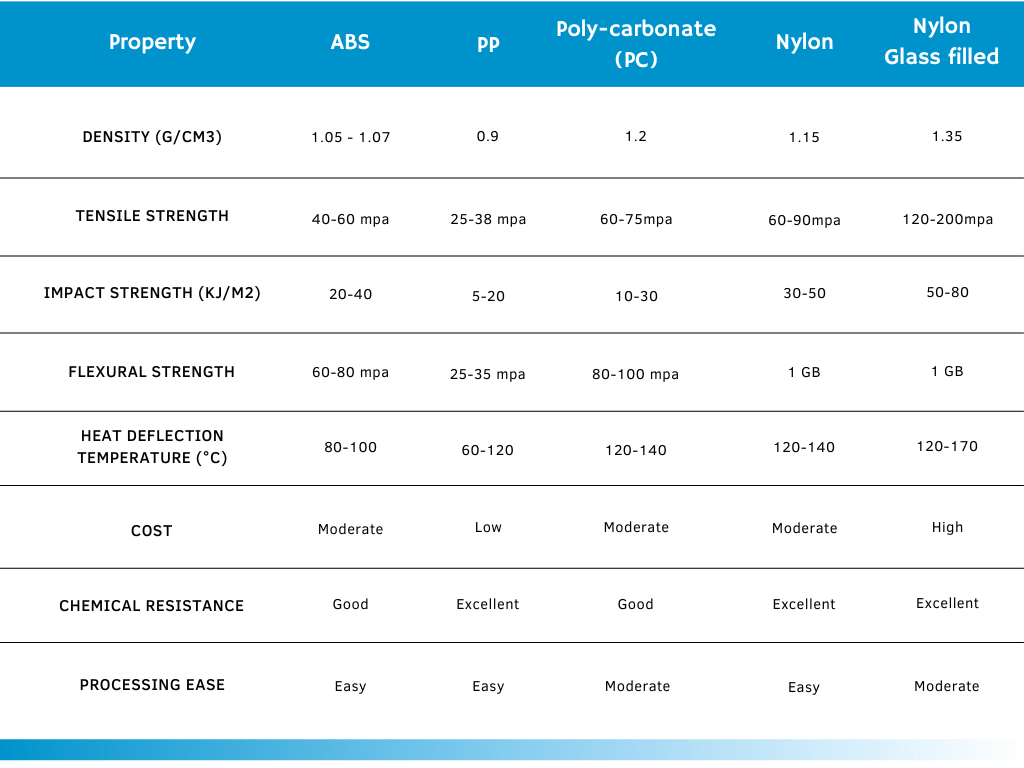

Comparison of Injection molded plastics