Rubber molding

Automotive parts

Gaskets

Construction

Appliances

Advantages of Rubber molding

Rubber has good tear resistance and sealing properties. Its one of the most widely used material to make washers, gaskets for enclosures and flexible parts

- Tear resistance

- High flexibility

- Fast molding

- Variable shore hardness

Rubber molding grades

We help you make Rubber molded parts with the properties you need

Standard Rubber types

- Neoprene

- EPDM

- Nitrile

Rubber shore hardness

- 20

- 40

- 60

- 80

Design guidelines for Rubber molding

Minimum wall thickness for Rubber parts

A minimum wall thickness of 0.5mm to a maximum of 6mm can be achieved for Rubber parts. Rubber flows well even in small areas

Uniform wall thickness

A uniform wall thickness should be maintained throughout the part to ensure smooth flow of material. Inconsistent wall thickness will hamper filling

Draft angles

ABS injection molded parts generally have a 1 – 2 degree draft to ensure easy removal of part from the mold

Sharp corners

A fillet has to be added in all sharp corners to ensure easy flow of material

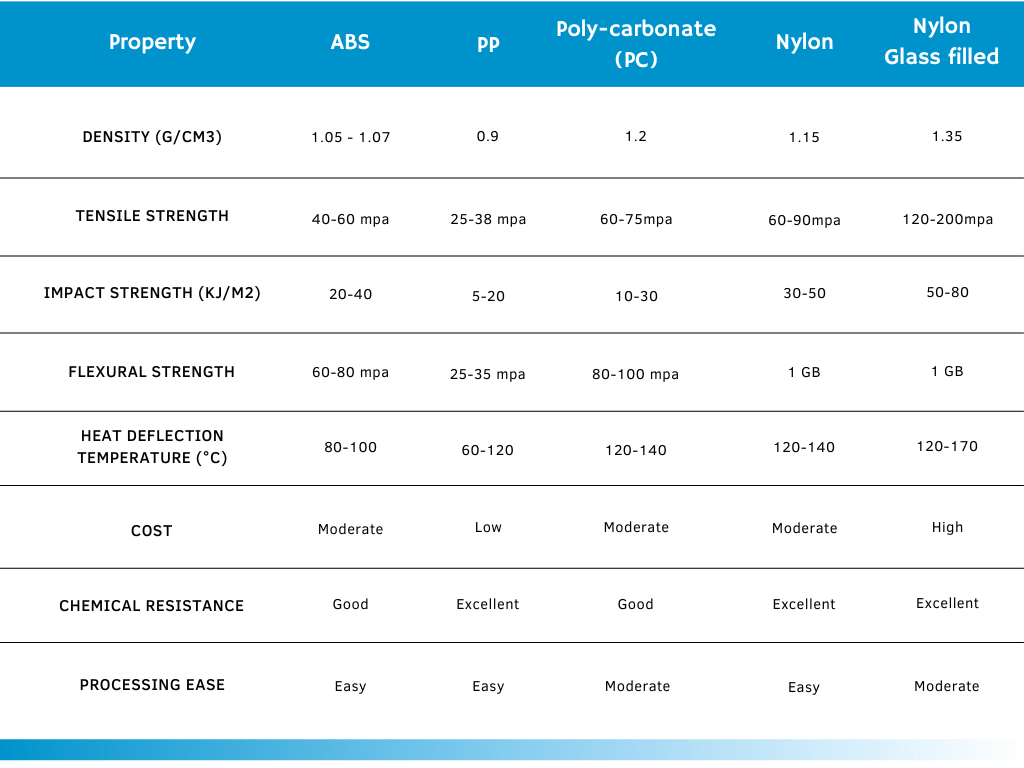

Comparison of Injection molded plastics