Silicon molding

Automotive parts

Enclosures

Medical equipment

Appliances

Advantages of Silicon molding

Silicon rubber is a good material to make food grade parts which require flexibility . Its also used to make protective casings for enclosures which are sensitive to heat. We can make gaskets, sleeves, washers with silicon in different shore hardnesses

- High flexibility

- High Heat resistance

- Food safe

- Tear resistance

- Different hardness available

Silicon molding grades

We help you make Silicon molded parts with the properties you need

Silicon hardnesses

- 20 – 60

Design guidelines for Silicon molding

Minimum wall thickness for Silicon parts

A minimum wall thickness of 0.5mm to a maximum of 6mm can be maintained for Silicon parts. It flows well since its a high viscous material

Uniform wall thickness

A uniform wall thickness should be maintained throughout the part to ensure smooth flow of material. Inconsistent wall thickness will hamper filling

Draft angles

Sharp corners

A fillet has to be added in all sharp corners to ensure easy flow of material

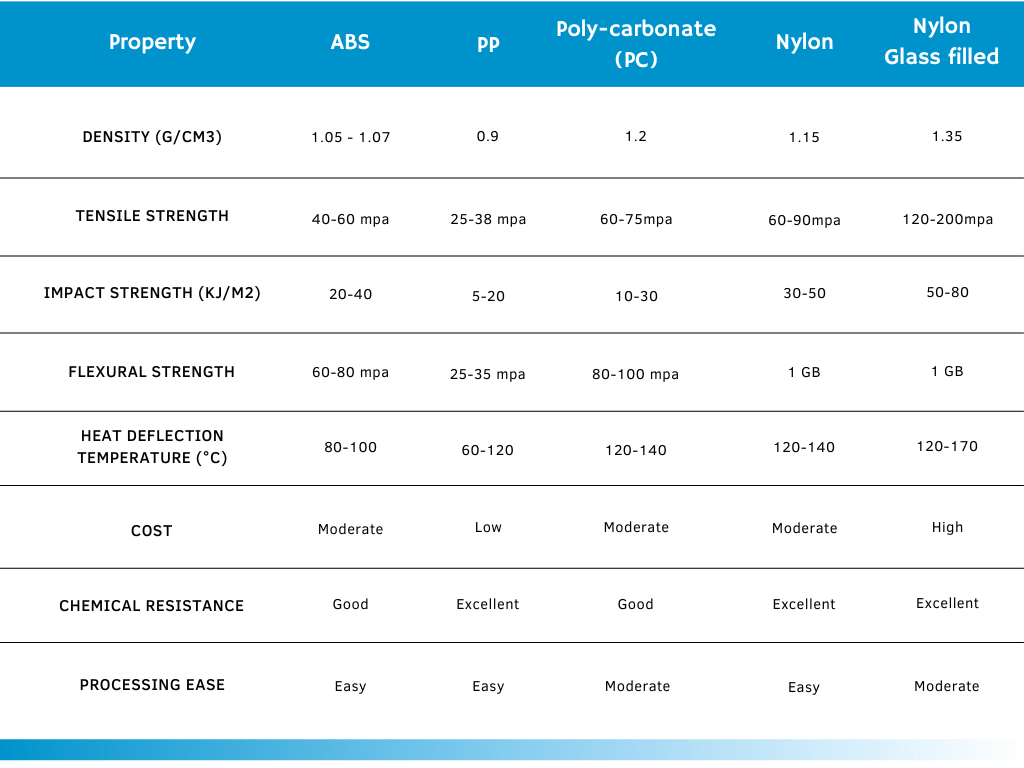

Comparison of Injection molded plastics