The Hidden Hero of Every Smart Device

When you think about IoT innovation, sensors and software often come to mind first. But every successful IoT product shares one silent hero — its enclosure. Your enclosure protects, defines, and differentiates your device. It’s not just a box; it’s your brand’s first impression and your product’s first line of defence.

At Precious3D, we help IoT startups and manufacturers create custom IoT enclosures that balance form and function – designed for manufacturing, durability, and scalability.

What Makes a Great IoT Enclosure?

A great IoT enclosure does more than look good. It ensures usability, protection, and easy manufacturability. Here’s what defines an exceptional enclosure:

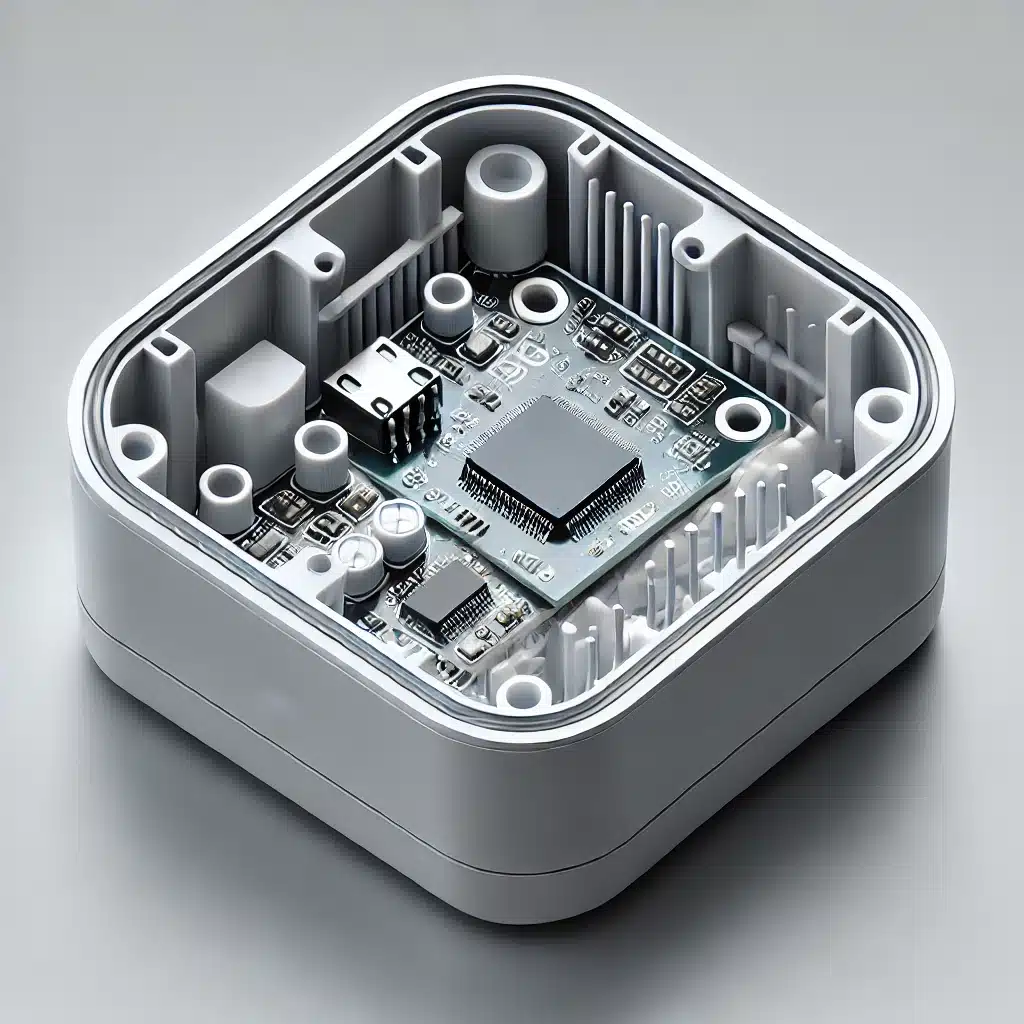

1. Smart Internal Architecture

Good internal architecture means fewer problems during assembly. We focus on correct PCB spacing, wire routing, and mounting points. Our 3D modeling and simulation tools help you achieve perfect fits for your boards, buttons, and ports.

2. Durable Material Selection

The right material can extend your device’s life, reduce maintenance, and enhance user satisfaction. Here’s a quick guide to choosing materials based on your product’s environment:

| Material | Best For | Key Benefits |

| ABS / PC-ABS | Indoor devices needing durability | Impact resistant, smooth finish |

| FR-ABS / PC | High heat or flame-prone areas | Flame retardant, heat resistant |

| Nylon / PA | Industrial or mechanical use | High strength, chemical resistance |

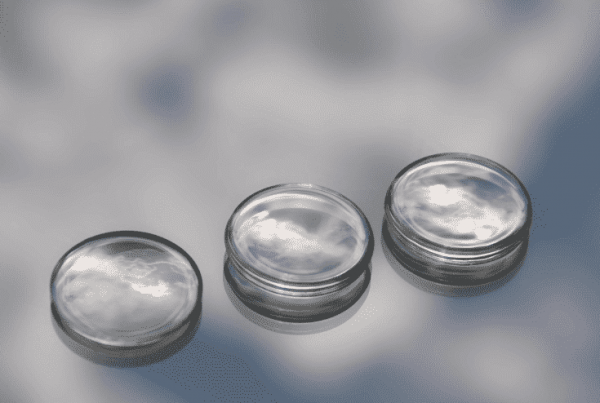

| Transparent PC | Sensor visibility or LEDs | High transparency, UV resistant |

3. Aesthetic Design

Your enclosure is your brand’s visual identity. Whether you want a minimalist, industrial, or futuristic look – our designers ensure it reflects your vision and feels right in users’ hands.

4. Manufacturing Feasibility

We design for real-world production. Start small with 3D printing or vacuum casting, and scale easily to injection molding when you’re ready for mass manufacturing — without redesigning.

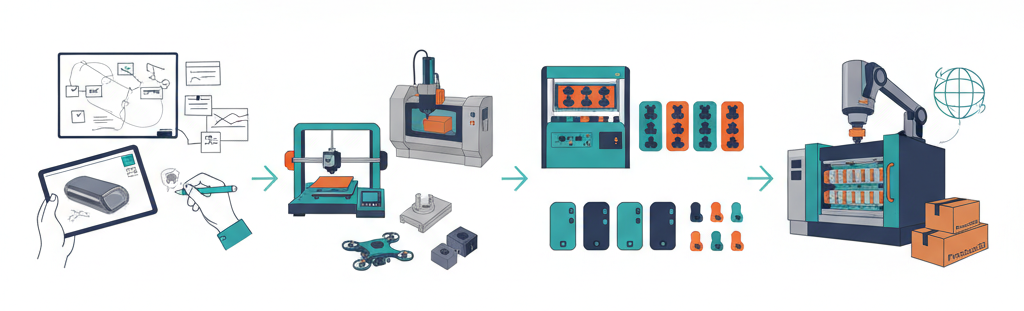

Our End-to-End Process

At Precious3D, we simplify your journey from concept to mass production with a complete design-to-manufacture workflow:

1. Concept Design

We understand your product’s function, size, and brand style, then convert your ideas into enclosure concepts aligned with your goals.

2. Prototyping

Using 3D printing (FDM, SLA) or CNC machining, we deliver prototypes in days — perfect for testing ergonomics and aesthetics.

3. Low-Volume Production

Need 100–500 units for investor demos or pilot launches? We use vacuum casting or soft tooling to deliver fast, affordable results.

4. Mass Production

Once validated, we move seamlessly to injection molding for large-scale manufacturing — ready for export worldwide.

Why Startups Choose Precious3D for Custom IoT Enclosures

- Low MOQ – start with as few as 100 pieces.

- Fast iterations – prototype in under 10 days.

- Expert material guidance for mechanical and electrical needs.

- Export-ready solutions serving India, USA, UAE, Singapore, and Europe.

- No tooling investment – we handle design and production through our partner network.

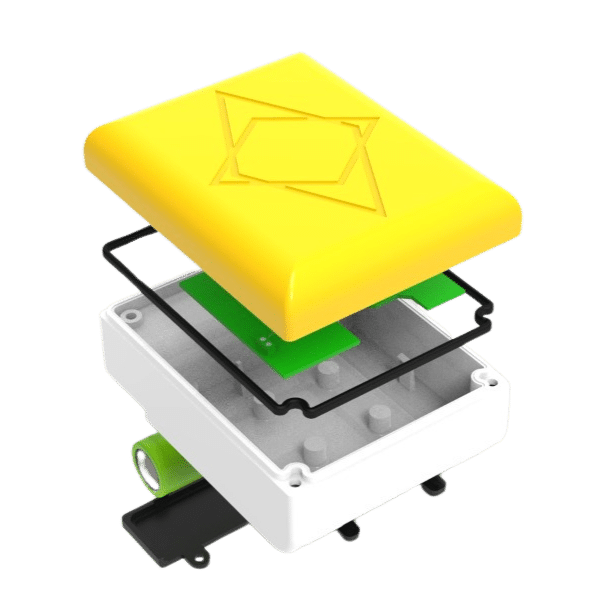

Case Study: Scaling from 50 to 5000 Units

A UAE-based IoT startup needed a premium enclosure for a smart building sensor. With limited tooling budget and a tight timeline, we designed a two-part FR-ABS enclosure with silicone sealing and snap-fit locks. We produced 10 3D printed prototypes and made a manual mold for making first 100 components. After validation, production scaled to 5000 injection-molded units – all within two months

The Future of IoT Hardware Design

In 2025, hardware success depends as much on design as it does on intelligence. According to Deloitte’s IoT Trends Report 2025, 73% of startups that invest in enclosure design reduce production costs and improve reliability. A great enclosure shortens assembly time, strengthens brand trust, and extends product life – that’s what Precious3D delivers.

💬 Ready to Build Your Custom Enclosures?

Whether you’re a startup creating your first IoT device or an established brand optimizing your product design, we can help.

👉 Let’s discuss your project.

Visit www.precious3d.com

or email us at support@precious3d.com

to get your enclosure designed and manufactured

IOT enclosures Frequently asked questions

What is an IoT enclosure?

It’s a protective casing that houses your IoT device’s electronics, sensors, and power components.

Why should I choose a custom enclosure over a standard one?

Custom IoT enclosures ensure perfect fit, better durability, and unique design for your brand.

What materials work best for outdoor IoT devices?

FR-ABS, PC, and PA are common for weather resistance and high mechanical strength.

How long does it take to go from design to prototype?

Precious3D typically delivers prototypes within 7–10 days after concept approval.

Can I start with low quantities?

Yes. You can begin with as few as 100 pieces and scale later to thousands without redesigning.