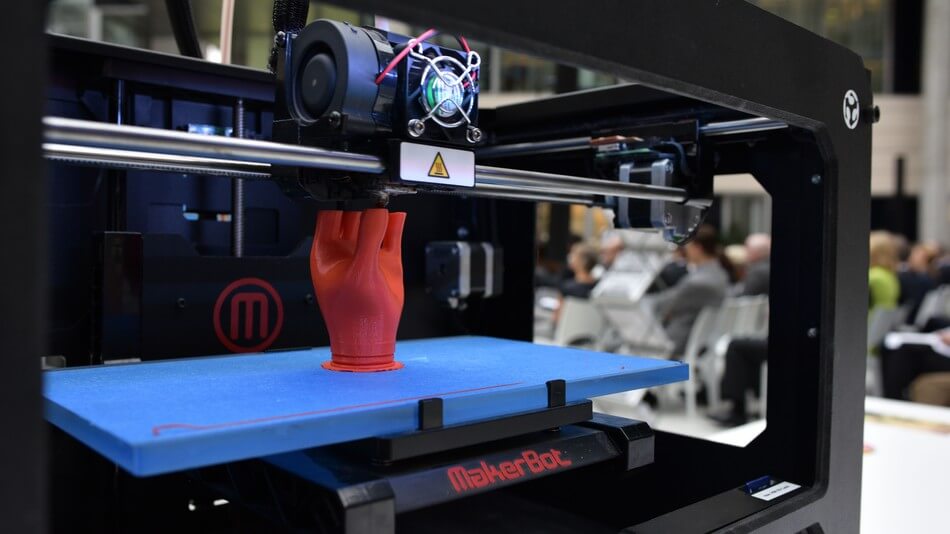

What is 3d printing technology?

3d printing service or additive manufacturing is a method of making three dimensional solid objects from a digital file. The creation of a 3d printed object is achieved using additive processes. In an additive process, an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

3d printing technology

Steps involved in the 3d printing technology

The various steps involved in 3d printing are as follows:-

CAD File Development

In order to produce a 3d object you first have to have its virtual design.

CAD File Conversions

The CAD file is converted into the specific file formats after it is developed. The file formats are specified based on the technology of printing being employed by that particular 3d printer.

STL File Manipulation

Now that the STL format file is ready for you, all your computer now needs is a 3d printer which can print using the stereolithography technique.

Preparing the Printer

Now that everything about the digital file is ready, one needs to make sure the 3d printer is ready. This means installing properly the polymers, binders and other material which are necessary to perform a print operation.

The Building Up

Once the process has started, it is now all about patience. These printers aren’t as faster as the 2d printers. Based on the complexity of the object to be printed, the span of printing varies. Simply all that one has to do is wait and perform random checks to make sure everything is being done flawlessly.

Post Processing Stuff

Once the entire process is done and the object is ready, the object is to be handled carefully. Any actions in haste could prove to be costly.

Working of 3d printing technology

One starts by designing a 3d object on an ordinary home PC, connect it to a 3d printer, press ‘print’ and then sit back and watch. The process is a bit like making a loaf of sliced bread but in reverse. Imagine baking each individual slice of bread and then gluing them together into a whole loaf (as opposed to making a whole loaf and then slicing it, like a baker does). That’s basically what a 3d printer does.

The 3d printing process turns a whole object into thousands of tiny little slices, then makes it from the bottom-up, slice by slice. Those tiny layers stick together to form a solid object. Each layer can be very complex, meaning 3d printers can create moving parts like hinges and wheels as part of the same object. One could print a whole bike – handlebars, saddle, frame, wheels, brakes, pedals, and chain – ready assembled, without using any tools. It’s just a question of leaving gaps in the right places.

3d printing technology vs Traditional manufacturing

Saves Time

By utilizing additive manufacturing, one can get to market quicker by avoiding wasting valuable time waiting for retooling. If reworking the design is necessary, adjustments can simply be made to the CAD file and programmed into the 3d printer.

Conserve Money

Because retooling is unnecessary, one avoids having to pay for the costly changes to an assembly line that retooling can require. This means that one can order a single 3d prototype at a fraction of what it would cost using traditional manufacturing.

Reduce Waste

Unlike traditional manufacturing methods which can result in lots of waste that may not be correctly recycled, the only material that is consumed via additive manufacturing is the actual material used for the end-product.

Product Innovation

With additive manufacturing, one gains the ability to make parts that simply can’t be produced by traditional means. Parts can be printed with multiple integrated components, made to perfectly fit together with other 3d printed projects, and include gradients of color. Advances in 3d printable materials mean that the industry can now print in countless new materials. The result is that beautiful, complex, and durable end products can be produced through industrial additive manufacturing.

Future of 3d printing technology

Ultimately, when we look at the potential of 3d printing technology, it’s clear that mass manufacturing will not be completely eradicated. Its efficiency and scale have clear benefits for specific product categories. Nonetheless, 3d printing has the potential to create a whole new powerful product category. It eliminates the need for complex supply chains and excessive waste while decentralizing production, wealth and knowledge.

In the long run, 3d printing can help create a “decentralized, rural-based, self-reliant economy,” where production and consumption are once again reunited.

Read more: