Injection Molding for Medical Devices: The Real Backbone of Modern Healthcare

Let’s be honest — when you’re dealing with medical parts, there’s no room for “close enough.” You need precision. You need sterility. You need every piece to match the last one.

That’s why so many medical manufacturers rely on injection molding. It’s consistent, scalable, and built for strict hygiene standards. From syringes to surgical handles, most of the plastic parts used in hospitals start their life inside a mold.

At Precious3D, we’ve seen how this process turns ideas into safe, functional products — fast. Here’s how it fits into modern healthcare.

1. Why Injection Molding Works So Well in Medicine

You already know how tough the medical field is when it comes to standards. Injection molding checks every major box.

- Every part is identical, even across thousands of units.

- You can scale from 100 to a million without losing accuracy.

- It works with biocompatible and antimicrobial materials.

- And yes — it’s cleanroom-friendly.

In short, you get a method that’s built for mass production without compromising on safety.

According to Grand View Research (2025), over 55% of medical plastic components come from injection molding — and the market will cross USD 31 billion by 2027.

2. What Kind of Medical Parts Use Injection Molding?

You’ll find molded parts everywhere in a hospital.

Single-Use Items

Syringes, pill containers, IV connectors, and test tube caps.

Diagnostic Equipment

Covers and casings for glucose monitors, ECGs, or portable lab devices.

Most of these use materials like ABS, Polycarbonate, or PEEK — all proven safe and durable.

“Injection molding has made medical devices cheaper, cleaner, and easier to scale than any other process.” — Dr. Karen M., Biomedical Engineer (MedTech Journal, 2024)

3. The Role of Cleanrooms

Contamination kills credibility — and sometimes, more than that. That’s why many medical parts are molded inside ISO Class 7 or 8 cleanrooms. These rooms control air, dust, and microbes so nothing unwanted touches the final product.

If you don’t have access to such facilities, you can work with certified partners like Precious3D. We maintain controlled cleanroom environments that meet ISO and FDA standards.

4. Regulations You Can’t Ignore

Medical molding isn’t only about shaping plastic — it’s about passing audits. Here’s what every compliant manufacturer follows:

- ISO 13485 for medical device quality systems

- FDA / CE requirements

- Full traceability of materials and batches

- Compatibility with EtO, gamma, or steam sterilization

Injection molding supports these standards because it’s repeatable, documentable, and clean by design.

5. Rapid Prototyping & Small-Batch Production

Here’s the good part — you don’t need to wait months to test an idea. Using 3D printing and low-volume molding, medical startups can move from concept to sample in about 2–3 weeks.

We often see teams create:

- Proof-of-concept models for trials

- Preclinical test units

- Functional MVPs for investor demos

6. Why Manufacturers Stick With It

If you’re wondering why everyone uses molding – it’s simple:

- Precise results

- Minimal waste

- Fast turnaround

- Cleanroom-ready

- Compatible with sterilization

And because molds can last through thousands of cycles, your cost per part drops quickly.

7. What Precious3D Brings to the Table

We don’t just mold parts — we guide you from concept to compliant production. Here’s what you get with us:

- Material and design consultation

- 3D printing for prototypes

- Design-for-manufacturing support

- Certified cleanroom molding

We’ve worked with medical R&D teams, hospitals, and startups to bring ideas to life — reliably and on budget.

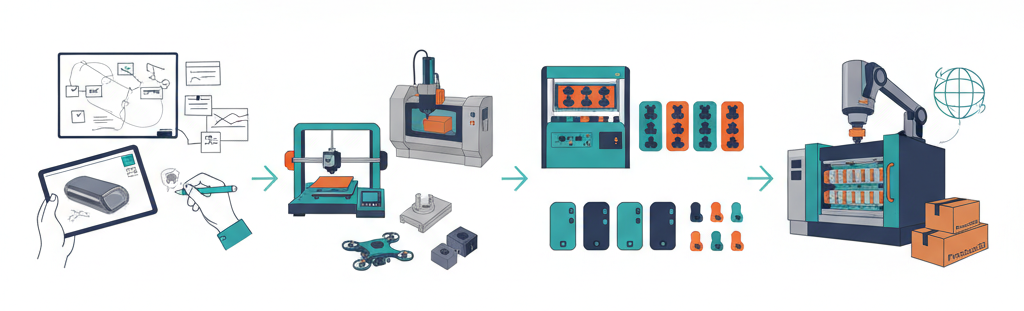

Our End-to-End Process

At Precious3D, we simplify your journey from concept to mass production with a complete design-to-manufacture workflow:

1. Concept Design

We understand your product’s function, size, and brand style, then convert your ideas into enclosure concepts aligned with your goals.

2. Prototyping

Using 3D printing (FDM, SLA) or CNC machining, we deliver prototypes in days — perfect for testing ergonomics and aesthetics.

3. Low-Volume Production

Need 100–500 units for investor demos or pilot launches? We use vacuum casting or soft tooling to deliver fast, affordable results.

4. Mass Production

Once validated, we move seamlessly to injection molding for large-scale manufacturing — ready for export worldwide.

Final Thoughts

Injection molding is the quiet hero behind modern healthcare. From small diagnostic casings to complex surgical tools, it keeps things accurate, sterile, and scalable.

If you’re developing a new medical device, start with a process that’s proven — injection molding. And if you want to get it right the first time, Precious3D can help you make it happen.

Frequently asked questions

What plastics are safe for medical molding?

ABS, PEEK, and Polycarbonate are common. They’re durable and can handle sterilization

Can molded parts be sterilized?

Yes — most medical-grade plastics work with EtO, gamma, or steam sterilization.

What cleanroom standard do medical molds follow?

Typically ISO Class 7 or Class 8.

How long does production take?

A prototype batch takes about 2–3 weeks; mass production depends on tooling.

Why should I choose Precious3D?

You get quick prototyping, and speedy manufacturing — all under one roof.