The advent of 3d printing has changed tremendously the way of manufacturing a component. The wide range of materials a printer can accommodate opens up new potential for environmental-friendly furniture and decor. Choosing additive manufacturing over traditional manufacturing proves to be a boon for the mother Earth as it produces much less wastage. In this era of pollution all around, this is a smart choice to make. 3d printing has led to the major transformation in the architectural field. The 3d printed architectural models have redefined the architecture.

Intricate designs depending upon a person’s interest can be designed in design software and scanned for printing purpose and when fed into the machine it gives the customer the designed product. Adding on to this the customer can also choose his own materials for the product.This makes the designer save time in searching for shops which have the product in the design which he thought of.

The technology of 3d printing provides the means to prototype designs that cannot be made through traditional manufacturing, which has opened the door to virtually limitless possibilities for the interior design industry. From light fixtures that take on the appearance of lace to bicycle-gear-shaped chandeliers, lighting designers have embraced 3d printing to create functional art for the home. Smaller decorative furnishings like creative containers, stools, and planters are less expensive, easier to print yourself, and adds visual interest to any interior. The main usage and point of attraction are objects can be produced as a whole or separate parts that make up the whole object to be produced. These separate parts can be joined together to incredible tolerances such that it is difficult to predict whether the whole object is produced from the machine or separate parts are produced and joined.This shows the accuracy of manufacturing components.

The best 3d Printed Architectural Models

3d printed concrete castle

3d printed castle

The first example of the best 3d printed architectural models is the 3d printed concrete castle made by a Minnesota based engineer named Andrey Rudenko. He with his two years of research and hard work in the field of technology came up with the idea and processing of a 3d printed concrete castle which is life-sized and capable of habitation. The walls of the small fortress, as well as three tops of the towers, have been fabricated separately and finally assembled into a single unit of free-standing structure. Looking at the castle no one can even doubt it not being a single unit that is the level of accuracy additive method of manufacturing has gained over the years. Not just this, time is consumed on a large scale.

3d printed hotel suite

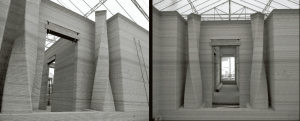

Construction phase of the 3d printed hotel suite

Lewis Grand Hotel

The second example of the best 3d print architectural models is the 3d printed hotel suite. A Grand suite hotel at the Philippines was built just in 5 days using 3d printing. Hotel owner Lewis Yakich has unveiled the world’s first 3d printed hotel suite—and it even comes with a spacious 3d-printed concrete jacuzzi. The 130-square-meter (1,500 square feet) structure was built for The Lewis Grand hotel in Angeles, Philippines, and took approximately 100 hours of print time to complete.

Yakich collaborated with Andrey Rudenko (the Minnesotan inventor of a 3d concrete printer and builder of the world’s first 3d printed concrete castle).

Their collaboration helped them to:

- Prepare and ship the 3d printer components over from Minnesota to the Philippines

- Assemble the machine

- Create the right concrete mix from local materials, including sand and volcanic ash.

The recently completed two-bedroom villa measures 10.5 meters by 12.5 meters and includes a living room and a jacuzzi room. Plumbing, wiring, and rebars are also installed in the structure

Sounds Impossible? Well, that is the true essence of this method, making impossible things possible.

Read more: