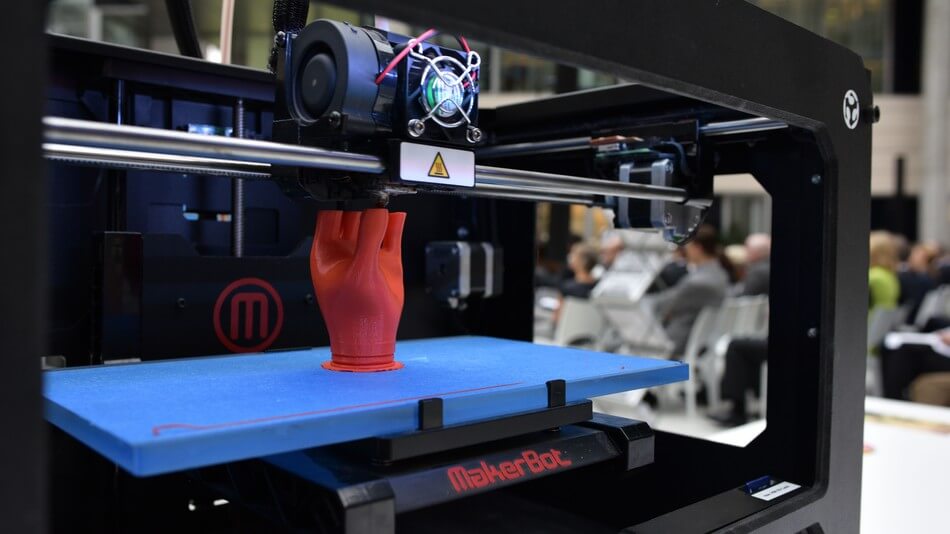

How Much Does 3D Printing Cost in India? A Complete Expert Breakdown for 2026

Clear pricing guide for materials, printers, design, finishing and delivery. Practical numbers you can use today.

Most people ask one practical question before they start: How much will 3D printing cost in India. This guide gives you direct answers. You will find material rates, the effect of different printers, design charges, finishing costs and real examples you can copy. Use this to plan a budget and avoid surprises.

Quick stat: India’s 3D printing market was about USD 707 million in 2024 and is growing above 20% CAGR through the decade

What decides your 3D printing cost

Your final price comes from five things:

- Material weight and type

- Printing time

- Printer type

- Design work

- Post processing and delivery

Material pricing per gram in India

Material cost is the biggest factor. You pay more for strength, detail or specialty materials.

Material

Price per gram

Best for

Example: A 100 gram PLA print usually lands between 1000 and 1500 rupees. The same part in resin often costs 2000 to 4000 rupees.

PLA 3D printing

Layer lines visible on surface

Cheaper cost

Good for quick sampling

Resin 3D printing

Smooth surface finish

High and intricate detailing can be captured

Premium look and feel

Printer types and hourly cost

Printer choice changes both finish and price. Choose the printer that fits the part need not the price tag alone.How print time affects cost

| Printer type | Average cost per hour INR | Typical use |

| FDM desktop | 200 to 500 | Low cost prototypes and sturdy parts |

| SLA or DLP | 500 to 1500 | Smooth finishes and small details |

| SLS or MJF | 1500 to 4000 | Small batch production and functional parts |

| Metal printing | 5000 to 10000 | Medical and aerospace parts |

Design charges if you need a model

If you have an STL file you save money. If not you need a designer to create a print ready file.

| Complexity | Price INR |

| Simple objects | 500 to 1000 |

| Medium parts with logos and small features | 1500 to 3000 |

| Complex mechanical assemblies | 5000 to 10000 |

Post processing and finishing

Finishing changes the look and increases cost. Consider which finishes you actually need.

Delivery and shipping within India

Delivery cost depends on weight, distance and urgency.

| Task | Approx price INR |

| Support removal | 100 to 500 |

| Sanding and smoothing | 200 to 1500 |

| Spray painting | 500 to 2000 |

| Resin curing and UV | 100 to 300 |

| Type | Range INR |

| Standard courier | 100 to 300 |

| Express or fragile delivery | 300 to 1000 |

Real cost examples for 2026

Custom name keychain

Material PLA, 12 grams, basic file

Cost 150 to 250 rupees

Branded phone stand

Material PLA, 80 grams, minor edits, FDM print, sanded

Cost 1200 to 2000 rupees

Gaming miniature

Material resin, 40 grams, SLA print, painted

Cost 2500 to 4500 rupees

Industrial electronics enclosure

Material ABS, 120 grams, custom CAD, industrial FDM, polished

Cost 5000 to 8000 rupees

Lead times in India

Prototype: 2 to 5 working days including design

Bulk after approval: 7 to 15 days

Large or complex batches: 20 to 30 days

Trends you should know from 2025

- Material prices stayed stable through 2024 and into 2025 which helps budgeting.

- Resin demand rose which lengthened lead times during busy months.

- Nylon PA12 and MJF gained wider use for low volume manufacturing.

- Metal printing stays premium because of maintenance and powder handling cost.

Expert notes

“You lower cost when you reduce surface area rather than volume. Many first time users miss this.” – R. Mehta, Additive Manufacturing Consultant

“Choose the right material for the job. Most teams over spend on resin where PLA does the job.” – Ankit Vora, Precious3D Engineering Lead

Frequently asked questions

How do 3D printing companies calculate cost in India?

They calculate material weight, printing time and post processing work. They add design charges if you need a model created.

Is 3D printing cheaper than CNC?

For prototypes and complex shapes 3D printing costs less. For high precision metal parts CNC can be cheaper at scale.

Do colors change the price?

No unless you use specialty color materials. Standard color choices do not add cost

How long does a typical print take?

Small prints finish in one to three hours. Larger prints take ten hours or more depending on detail.

Can I print flexible parts?

Yes you can print flexible parts using TPU or TPE material.

Do I need to prepare the 3D model before printing?

Yes you need an STL file. If you do not have one , we can appoint a designer to prepare it for you.