3d printing business: Ways 3d printing is changing the way we do business

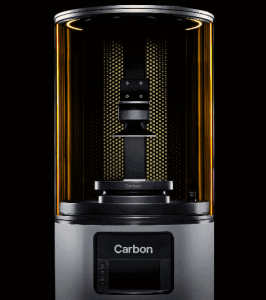

3d printing has loomed on the horizon for many years. Only now has the technology advanced to such an extent that we can confidently say it is becoming a practical part of the way businesses operate today. APWC survey revealed that 11% of manufacturing companies had already started to mass produce 3d printed parts. In addition, as quality continues to increase, 3d printing will continue to change the way we do business. Therefore, it is apparent that the 3d printing business is going to increase in future.

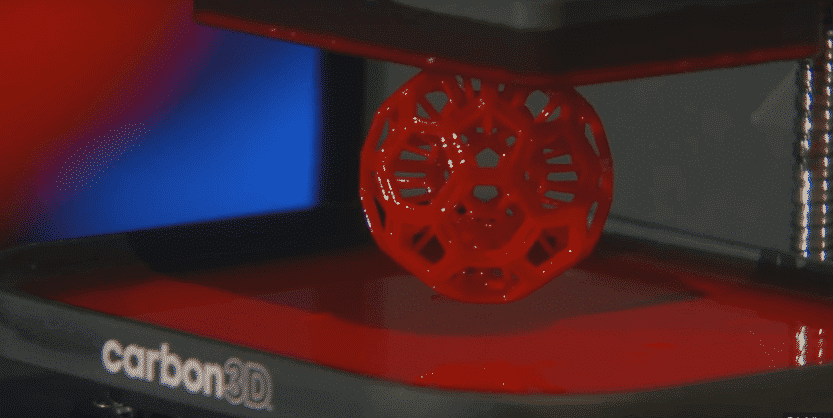

This article will investigate how 3d printing will change a variety of businesses. Products Coming to Market Faster: What a lot of people don’t know is that 3d printing has been used to create prototypes for over 20 years. However, this took time and three or four design cycles could take months. It meant new products took almost a year to actually make it to market.

Companies like UPS, have entered the arena and with same-day production and same-day delivery, design concepts that took months to build can happen in a matter of days. According to CGTrader.com,”3d printing has and will continue to open up truly rapid prototyping, enabling customers to get the products they crave faster.” From a business point of view, this forces everyone to move faster than ever before. Bigger companies that can afford this technology now have a distinct advantage, and smaller companies are either going to have to invest or fall.

Added Opportunities for Entrepreneurs in 3d printing business

The speed and increasing cost-effectiveness of 3d printing are providing massive opportunities for entrepreneurs. One of the reasons for this is simply due to how many industries 3d printing can touch. Entrepreneurs have always had the disadvantage of taking time to produce a prototype investor can look at. This is also extremely expensive so it meant many entrepreneurs could take years to actually begin raising money. The increasing accessibility of 3d printing will change the way we do business by opening up more chances for entrepreneurs to enter markets that were previously difficult to enter.

Will this mean additional innovation in 3d printing business?

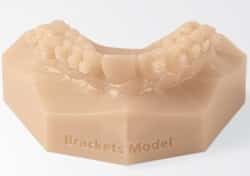

There is a good chance this is exactly what it will mean. Entrepreneurs will able to test more and be more daring.In the long-term, it could lead to faster innovations in a range of industries, including jewelry and surgical prosthetics.

A Boost for Small Businesses

Small businesses have a number of problems unique to them, particularly in the manufacturing industry. They lack the space needed for heavy machinery and storage. Also, they lack the funds for the latest innovations. They lack the time to produce a range of products. Most of the time, it is a matter of relying on that one great idea. 3d printing will change this. This technology can produce the same parts as other types of heavy machinery. The catch is it takes up a fraction of the space and costs but a fraction of the original price.

Small businesses will find that while they have no choice but to embrace the 3d printing revolution when they do they will be on better terms with their larger competitors. 3d printing will give the same benefits to a small company as it will a large company. 3d printing, once it becomes the norm, could start an era of rapid growth for small businesses. Increasingly, the business world will see small companies evolving into medium and large-sized organizations.

Should big companies be worried?

While this is certainly not a reason for big companies to begin worrying about competition, they should keep looking over their shoulders. No longer will be producing the same products with minor changes be acceptable. They will have to do more in order to continue to secure their dominance.

It is clear that 3d printing is set to change the world in many ways. Nowhere will this become more apparent than in business.For now, 3d printing will continue to improve. It will be a few years before it becomes the norm. However, companies that decide to act now will have a distinct advantage over their competitors. They will find that they have a lot to gain by opting for early 3d printing optimization. Additionally, it could lead to big things going forward for them.

Read more:

3d Printed Statues: Restoring History Using 3d Printing

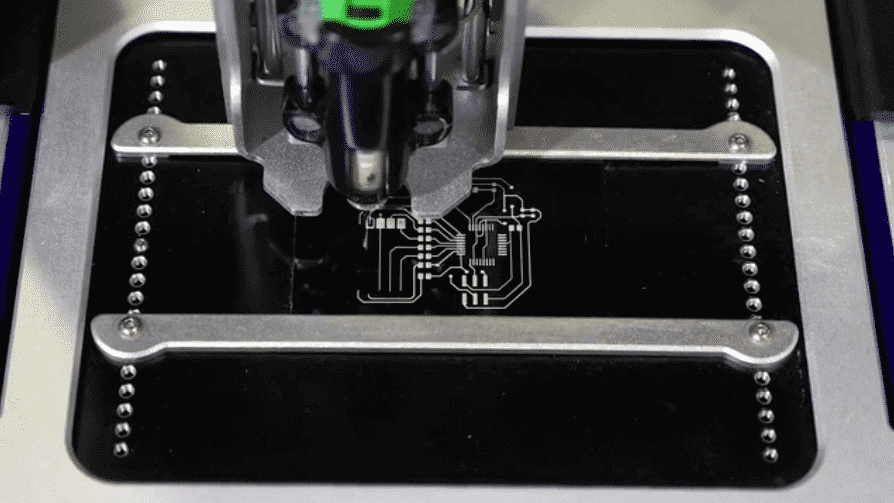

3d Printed Circuit Board: 3d Printing In Electronics Industry